-

M42 (HSS+8% Cobalt) Finishing CNC End Mill, 4 Flute, TiAlN Coating

- TiAlN Coated

- Single end

- Center cutting

- M42-8% Premium cobalt

- Flutes ground by a world-class IS-9002 Factory, CNC Qualified

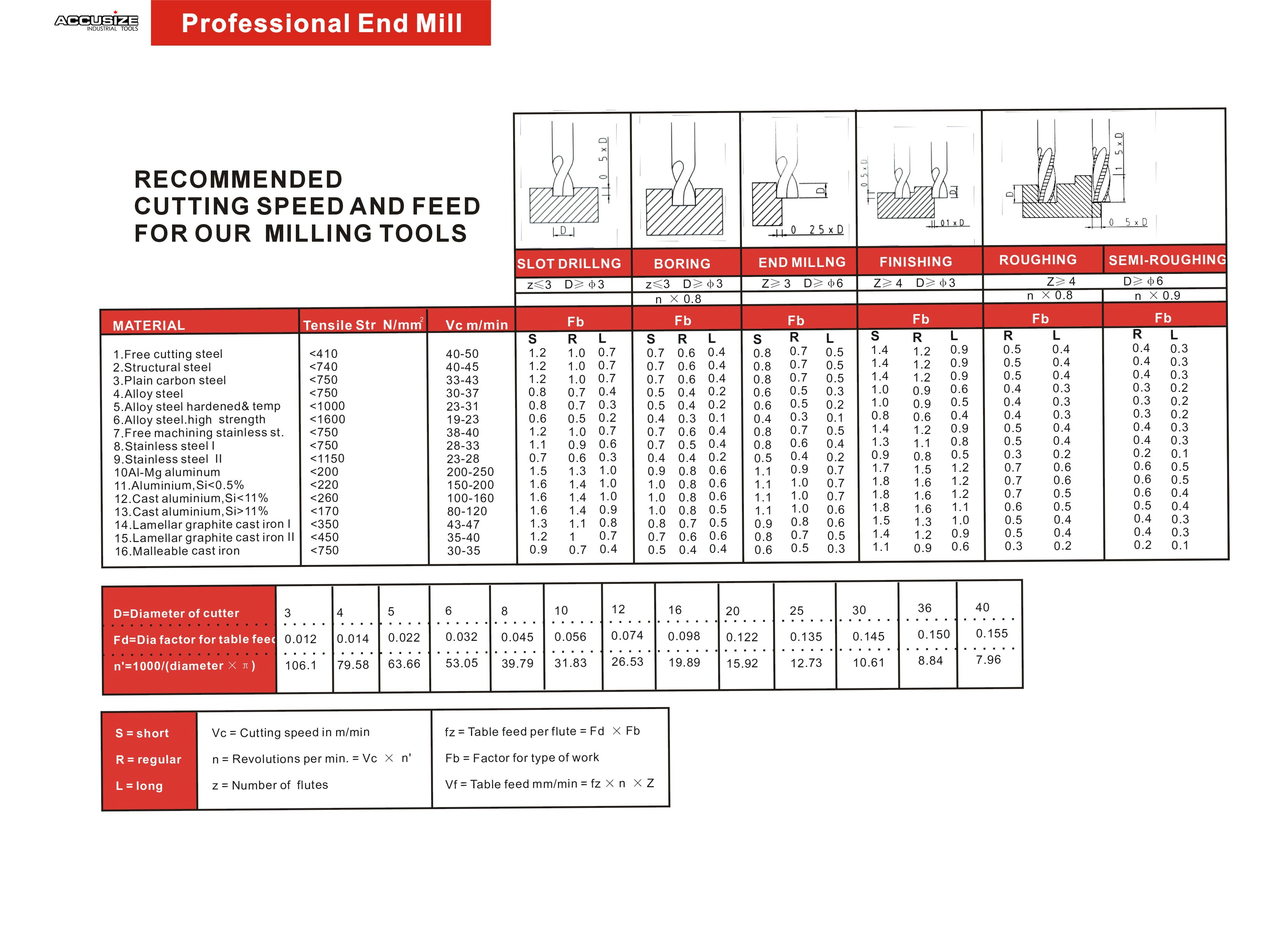

Item # Dia. Shk. Dia. Flt. Length Oal. 6800-4001 1/8" 3/8" 3/8" 2-5/16" 6800-4021 1/4" 3/8" 5/8" 2-7/16" 6800-4041 3/8" 3/8" 3/4" 2-1/2" 6800-4051 1/2" 1/2" 1-1/4" 3-1/4" 6800-4061 5/8" 5/8" 1-5/8" 3-3/4" 6800-4081 3/4" 3/4" 1-5/8" 3-7/8" 6800-4101 7/8" 7/8" 1-7/8" 4-1/8" 6800-4121 1" 1" 2" 4-1/2" Recommended Cutting Conditions for Roughing End Mills [Side Milling] Work Material Low Carbon Steels

(Tensile Strength: ≤180N/mm2) Copper

Alloys, Cast Iron(Soft)Medium Carbon Steels

(Tensile Strength: 480-720N/mm2)

Copper Alloys, Cast Iron(Hard)High Carbon Steels

(Tensile Strength: 720-950N/mm2)

Alloys Steel, Stainless SteelsSpecial Alloy Steels

Untree-cutting Steels

(30-40HRC)Aluminum,

Aluminum Alloys & PlasticMill Dia Ae Ad Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed (inch) (inch) (inch) (rpm) ( ft /min) (rpm) ( ft /min) (rpm) ( ft /min) (rpm) ( ft /min) (rpm) ( ft /min) 1/8" 0.0125" 3/16" 5035 0.347 3800 0.265 2518 0.134 1520 0.065 17100 1.115 1/4" 0.0250" 3/8" 2518 0.495 1900 0.370 1254 0.177 760 0.088 8500 1.394 3/8" 0.0375" 9/16" 1425 0.662 1064 0.495 713 0.236 428 0.121 4750 1.742 1/2" 0.0500" 3/4" 1121 0.626 855 0.469 570 0.223 337 0.121 3800 1.646 5/8" 1/16" 15/16" 903 0.557 675 0.419 451 0.223 266 0.124 2992 1.479 3/4" 0.0750" 1-1/8" 713 0.524 532 0.347 356 0.209 190 0.111 2375 1.394 7/8" 0.0875" 1-5/16" 637 0.495 475 0.311 318 0.183 171 0.101 1900 1.184 1" 0.1000" 1-1/2" 570 0.469 428 0.278 285 0.164 152 0.088 1710 1.115

- The Indicated speeds and feeds are

- For side milling with 2‐fluted end mill to a depth=0.1xD and a width of cut=1.5xD

- For milling with 4‐fluted, the feed should be twice that listed above.

- For finishing operations, the feed should be increased by 30�0%. 3.Use a rigid and precise machine and holder.

- Use suitable cutting fluids

Recommended Cutting Conditions for Roughing End Mills [Side Milling] Work Material Low Carbon Steels

(Tensile Strength: ≤180N/mm2) Copper

Alloys, Cast Iron(Soft)Medium Carbon Steels

(Tensile Strength: 480-720N/mm2)

Copper Alloys, Cast Iron(Hard)High Carbon Steels

(Tensile Strength: 720-950N/mm2)

Alloys Steel, Stainless SteelsSpecial Alloy Steels

Untree-cutting Steels

(30-40HRC)Aluminium,

Aluminium Alloys & PlasticMill Dia Ad Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed (inch) (inch) (rpm) ( ft /min) (rpm) ( ft /min) (rpm) ( ft /min) (rpm) ( ft /min) (rpm) ( ft /min) 1/8" 1/32" 4275 0.590 3192 0.419 1900 0.203 1330 0.111 10640 1.397 1/4" 1/16" 2128 0.839 1615 0.557 950 0.369 675 0.157 5320 1.758 3/8" 3/32" 1186 1.115 903 0.734 532 0.354 380 0.209 2992 2.230 1/2" 1/8" 950 1.062 713 0.656 428 0.334 299 0.209 2375 2.093 5/8" 5/32" 760 0.951 570 0.623 337 0.334 238 0.223 1900 1.922 3/4" 3/16" 599 0.892 451 0.531 266 0.314 190 0.223 1520 1.758 7/8" 7/32" 532 0.839 404 0.472 238 0.282 171 0.203 1330 1.673 1" 1/4" 475 0.780 356 0.419 213 0.249 152 0.177 1188 1.561 Ad=1/4D

- The Indicated speeds and feeds are for slotting

- depth=1/4xD

- For deeper slotting , the speed should be decreased by 20-50%

- Use a rigid and precise machine and holder.

- Use suitable cutting fluids

**ABOVE CUTTING PARAMETERS PROVIDED FOR REFERENCE ONLY **

-

Product NameMaterial Number