TRADESMAN MACHINIST END MILL WORKSTATION

-

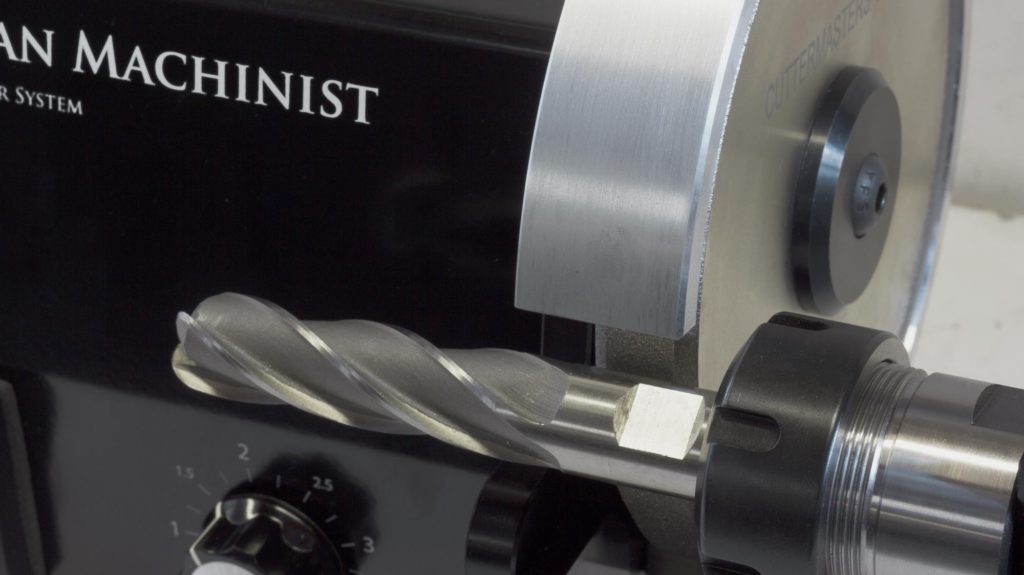

Neck relief / tool shank diameter reduction

-

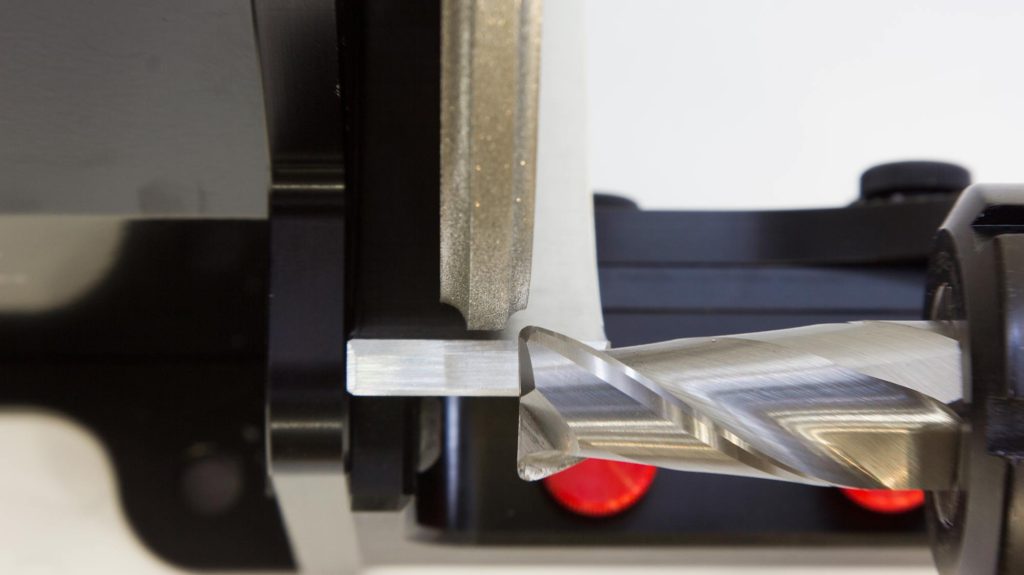

Weldon set screw flats

-

Carbide cut off

-

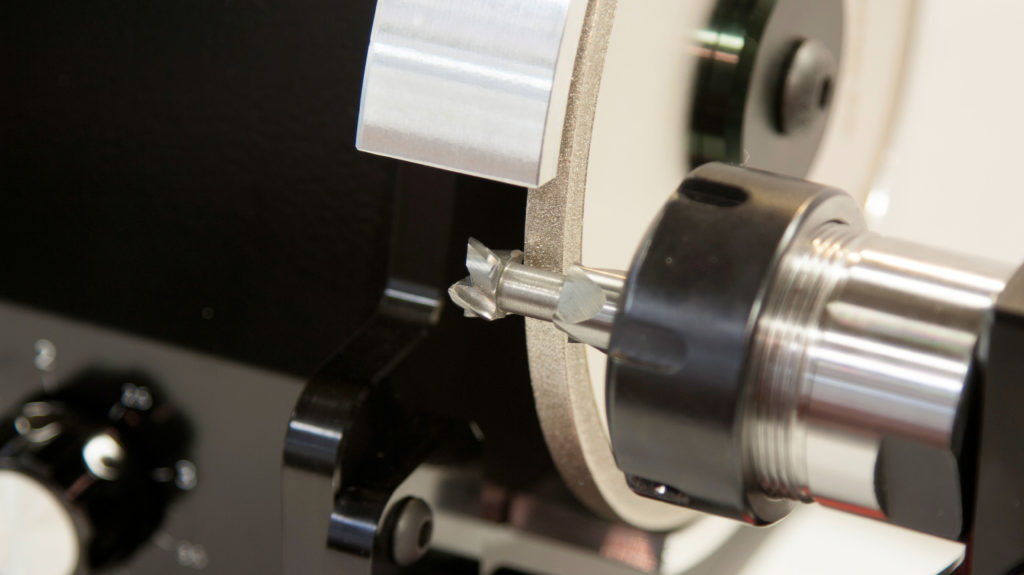

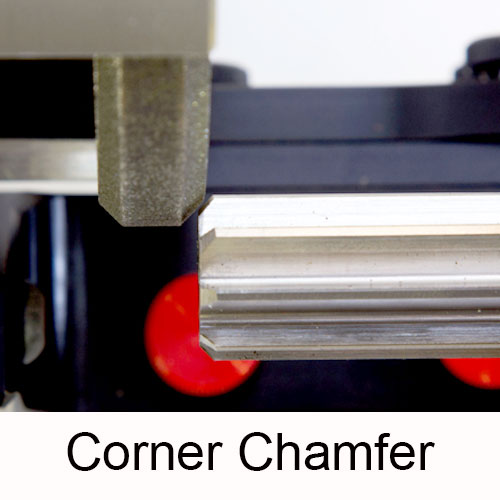

Corner chamfer

-

This package includes your choice of grinding wheel (choose from drop down menu above)

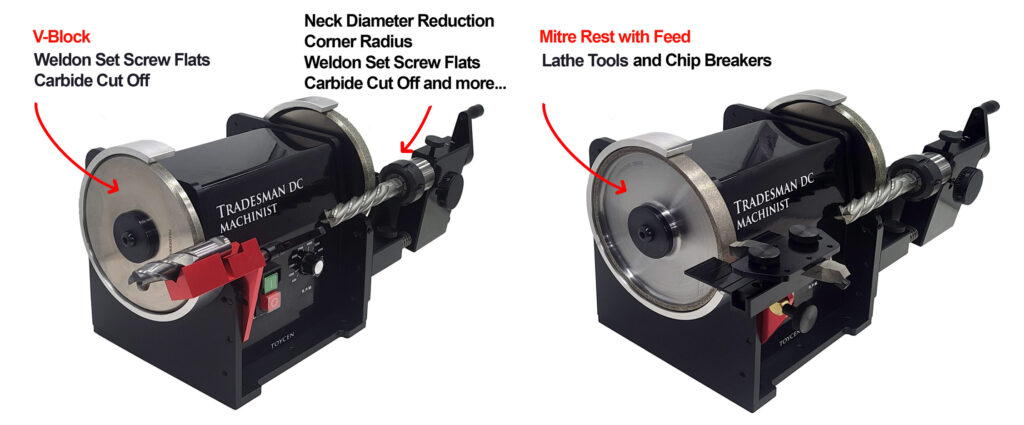

The benfit of the dual shaft Tradesman is that you can set up a second operation on the other side. This package has the spinning ER32 tool holder on the right side (necks, flats, cut off, reamers) and a standard tool rest on the opposite side. Options for the other side are lathe tools (Mitre Rest with Feed), flats, cut off (V-Block or second ER32 tool holder), or standard rest (included)

Cuttermasters Precision Plated CBN and Diamond Grinding Wheels are balanced and always flat, so no extra grinding dust. When you use the Tradesman Grinder with it’s DC motor you find you can grind heavy cuts, at below 1000 rpm, keeping the grinding process cool and quiet. If you want to put a .005 radius/chamfer on something, you can hear when the tool contacts the wheel.

Neck reduction: This often needed grind is quick and easy with the Tradesman Machinist T-ER32 Neck Grinding Attachment and one of our diamond plated Shoulder Wheels. This same set up is perfect for creating your own T-cutter out of a standard end mill with our CBN Shoulder Wheels.

The tool you need for a job may not have an important feature: the set screw flat. Quickly add a perfect set screw flat or Weldon flat using the T-ER32 Neck Grinding Attachment and one of our Chamfer Wheels. This same set up is perfect for reducing the neck diameter of your CBN and carbide tools. However you may prefer one of our Shoulder Wheels for neck diameter relief / reduction as there is no chamfer which allows for closer approach to the collet chuck.

Cut off your carbide tools with our Diamond Resin Bond Cut Off Wheel or our Diamond Plated Cut Off Wheel. The resin bond wheel will cut more tools while the plated wheel will cut faster. Use the T-ER32 tool holder or V-block tool holder

Use our chamfer wheels to sharpen tools, like reamers, by indexing around to each flute. This requires the indexing version of the T-ER32 Tool Holder so add the T-ER32 (upgrade) to this package for that option. As this operation uses the side of the wheel the precision shaft option is also required

Grind rads quickly and easily with our Profiled Radius Wheels. Grind .02″, .03″, .04″, .06″, .09″ and .12″ corner rads. Our T-ER-32i Neck Grinding Attachment indexes to flute positions for 2, 3, 4, 6 and 8 flute end mills and allows you to plunge grind a radius (YouTube video).

The Tradesman Machinist is probably the highest accuracy grinder in its class. Still, the precision required to achieve a good corner radius demands that the motor tolerances are tighter than usual so a motor with this additional accuracy is required at the time of purchase if intended for corner rads.