-

CAT50 Collet Chuck Tightening Fixture Fit CAT50 Tool Holder as well as SK50 and JT50 Holder, CT50-7850

- Applicable model is CAT50, SK50 and JT50

- Correct orientation and non-slip quench hardening

- Easy to install and reliable, protect tool holders, bear greater torque and avoid skidding

- The material is aluminum alloy

- Novel hollow design, protect the conical surface of the tool holder.

- Adopt new material, detailed and comprehensive protection.

- Match for CT50 tool holder type as well as SK50 and JT50

Applied new materials and detailed and comprehensive protection.

CAT50 / SK50 / JT50 Collet Chuck Tightening Fixture

- Applicable model is CAT50 as well as SK50 and JT50 tool holders

- Correct orientation and non-slip quench hardening

- Easy to install, reliable, protect tool holder, could bear greater torque, avoid skidding

- The material is aluminum alloy

- Novel hollow design, protect the conical surface of the tool holder.

- Adopt new material, detailed and comprehensive protection.

- Match for CT50 tool holder type as well as SK50 and JT50

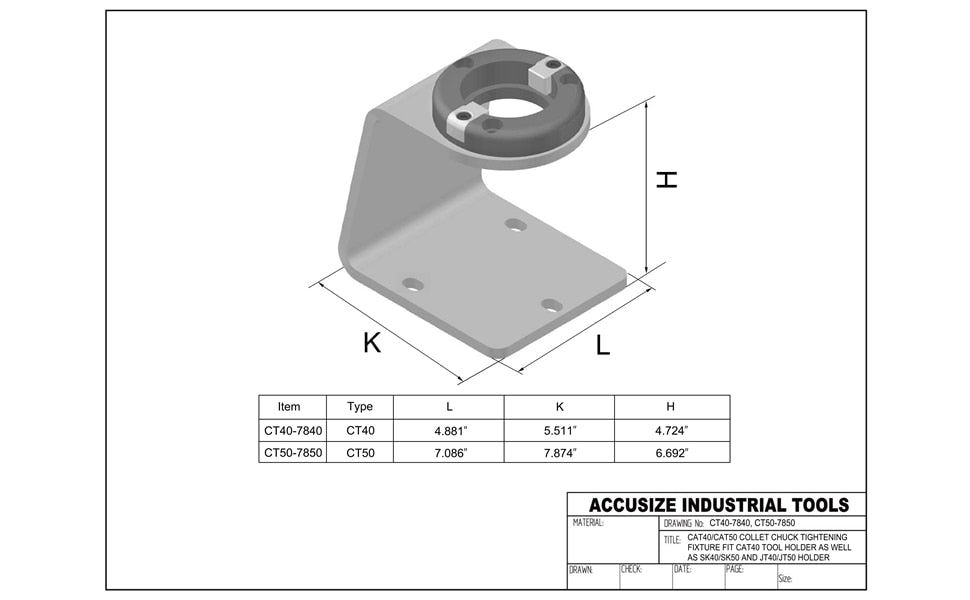

Specification

Novel overall designed to protect the taper of tool holders

Compared to the traditional cone design, the U-shaped hollow structure design is less likely to damage the taper surface of the tool holders by avoiding the contact between the tool holders and the base of the tightening fixture.

Operating

- Fix tightening fixture before use.

- After placing the tool holder, tighten it with positioning blocks.

- As shown in the photo above, the pull studs and nuts are respectively mounted and dismounted by the fixing grooves.