-

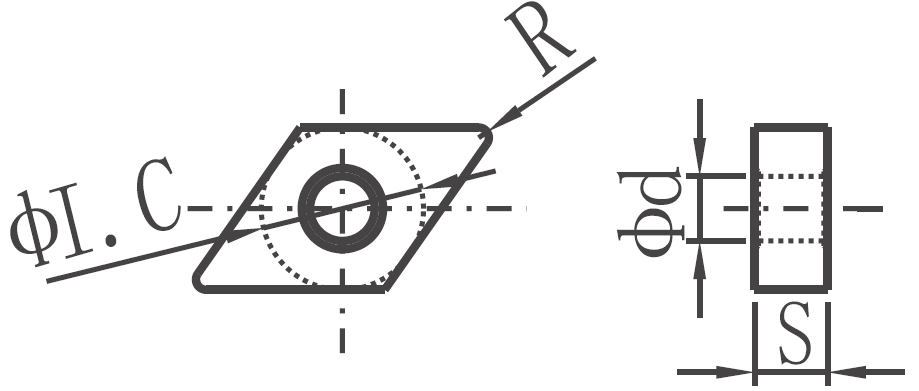

DNMG332, 432 & 442 Carbide Inserts, CVD Coated, Black/Yellow, 10 ps/box

Accusize DNMG inserts are double-sided 55° rhombic carbide Inserts for machining a broad range of metal materials at medium cutting conditions. When a cutting edge of the DNMG insert becomes dull, you just need to rotate the insert in the holder to use the sharp edge. The CVD coating of the inserts provides significantly longer tool life than uncoated inserts.

- CVD Coated

- Insert Grade: BPS101

- Chip Breaker: MD

- Material: Carbide

- DNMG

- Coating: CVD Al2O3 TICN

- Machining Parts Material: Steel

- Machining Process: finish

Features

- Grade for finish turning.

- Substrate having excellent resistance to thermal crack and plastic deformation, strong resistance to chipping.

- New coating technology, can withstand high temperature when machining with or without coolant; long tool life.

- The outermost side is yellow color TiN coating, which ensures the performance of the coating and makes wear conditions easier to identify.

- Composite coatings provide increased wear resistance and service life for cutting edges.

- TiCN enhances coating adhesion, thereby ensuring edge strength.

- The matrix adopts layer distribution cemented carbide to ensure wear resistance at the same time, provides excellent resistance to plastic deformation and edge toughness.

Item # Product # ANSI # I.S.O. # I.C Thickness Hole Radius 6206-1026 2206-1026 DNMG332-P3 DNMG110408-P3 3/8" 3/16" 0.150" 1/32'' 6206-1028 2206-1028 DNMG432-P3 DNMG150408-P3 1/2'' 3/16'' 0.203'' 1/32'' 6206-1029 2206-1029 DNMG442-P3 DNMG150608-P3 1/2'' 1/4'' 0.203'' 1/32''